Annealed vs. Hardened Stainless Steel: Understanding the Difference

When selecting stainless steel for your project, understanding the difference between annealed and hardened states is crucial for optimal performance. Ruixiang Steel provides both types, each with distinct properties tailored to different applications. Let's explore these differences to help you make an informed decision.

What is Annealed Stainless Steel?

Annealing is a heat treatment process that alters the microstructure of stainless steel to enhance its ductility and reduce hardness. The process involves heating the material to above its recrystallization temperature, maintaining this temperature for a specific duration, and then slowly cooling it down .

This thermal treatment serves to release internal residual stresses and restore properties that may have been reduced during cold working. The result is a material with increased softness, ductility, and toughness .

For stainless steel, annealing can be performed in a controlled atmosphere to prevent surface oxidation. The bright annealing process, for instance, utilizes a hydrogen-nitrogen mixture to create a smooth, shiny, and scale-free surface while enhancing corrosion resistance .

What is Hardened Stainless Steel?

Hardened stainless steel has undergone treatments to increase its strength and wear resistance. While standard stainless steels can be hardened through cold working, a special category known as precipitation hardening stainless steel achieves high strength through specific heat treatments .

These specialized stainless steels contain added elements such as copper, aluminum, titanium, or aluminum, which form precipitates during aging treatments, significantly enhancing strength while maintaining adequate toughness .

Choosing the Right Option

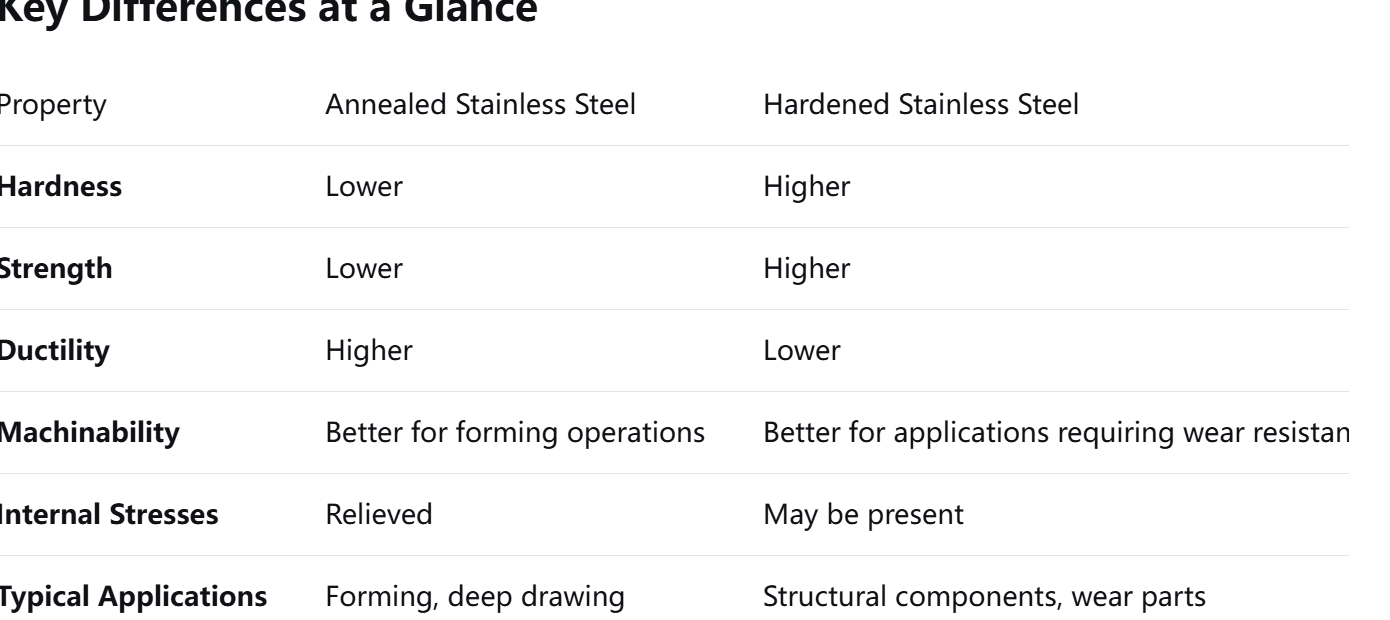

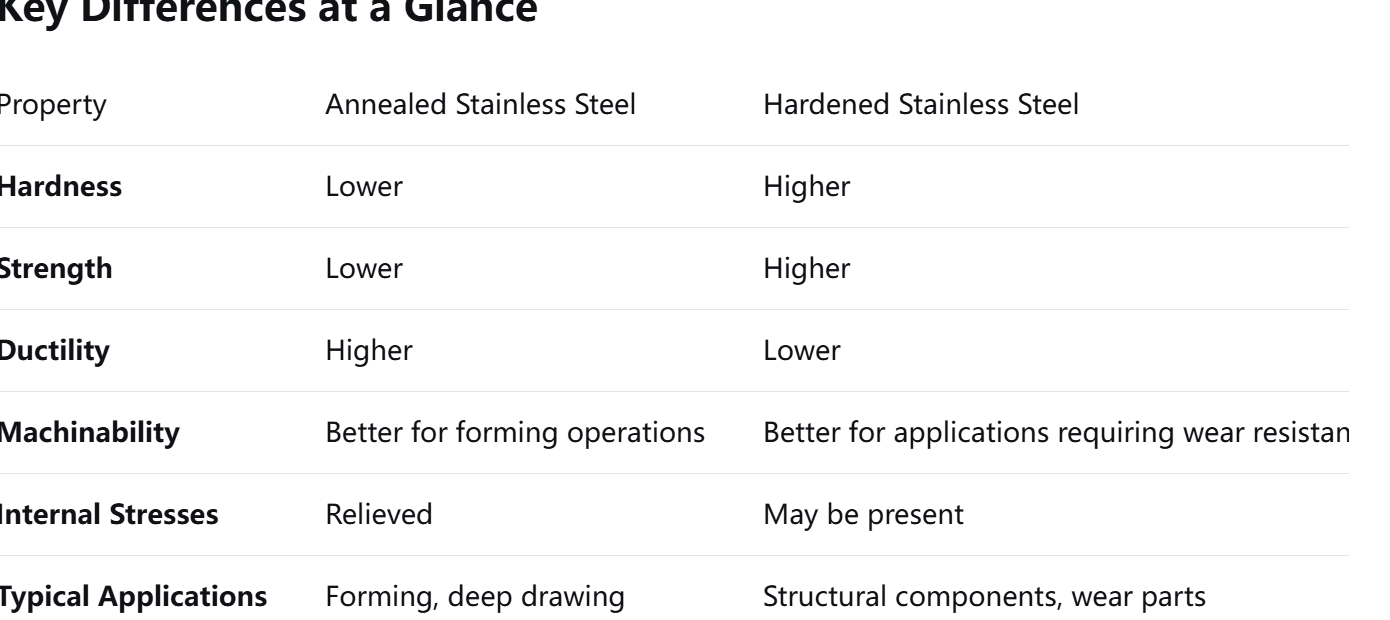

The choice between annealed and hardened stainless steel depends entirely on your application requirements:

Choose annealed stainless steel when you need maximum ductility and formability, such as in deep drawing, spinning, or forming operations. The annealed state is also preferable when you need to minimize internal stresses for dimensional stability .

Choose hardened stainless steel when your application demands high strength, hardness, and wear resistance. Typical applications include aerospace components, high-stress structural parts, and applications where resistance to deformation is critical .

Ruixiang Steel offers comprehensive solutions for both annealed and hardened stainless steel, ensuring you receive the right material specification for your specific project needs.

Click:656Edit: Admin

Click:656Edit: Admin Time:2025-10-03 19:57:14

Time:2025-10-03 19:57:14