In the world of industrial piping,

ASTM A106 and

ASTM A53 are two of the most common specifications. At first glance, they appear identical, and in many commercial applications, their mechanical properties overlap. However, choosing the wrong one can lead to project failure, especially in high-pressure or high-temperature environments.

In this guide,

Rui Xiang Steel breaks down the 5 essential differences to help you make an informed procurement decision.

1. Manufacturing Process: Seamless vs. Welded

The most fundamental difference lies in how these pipes are made.

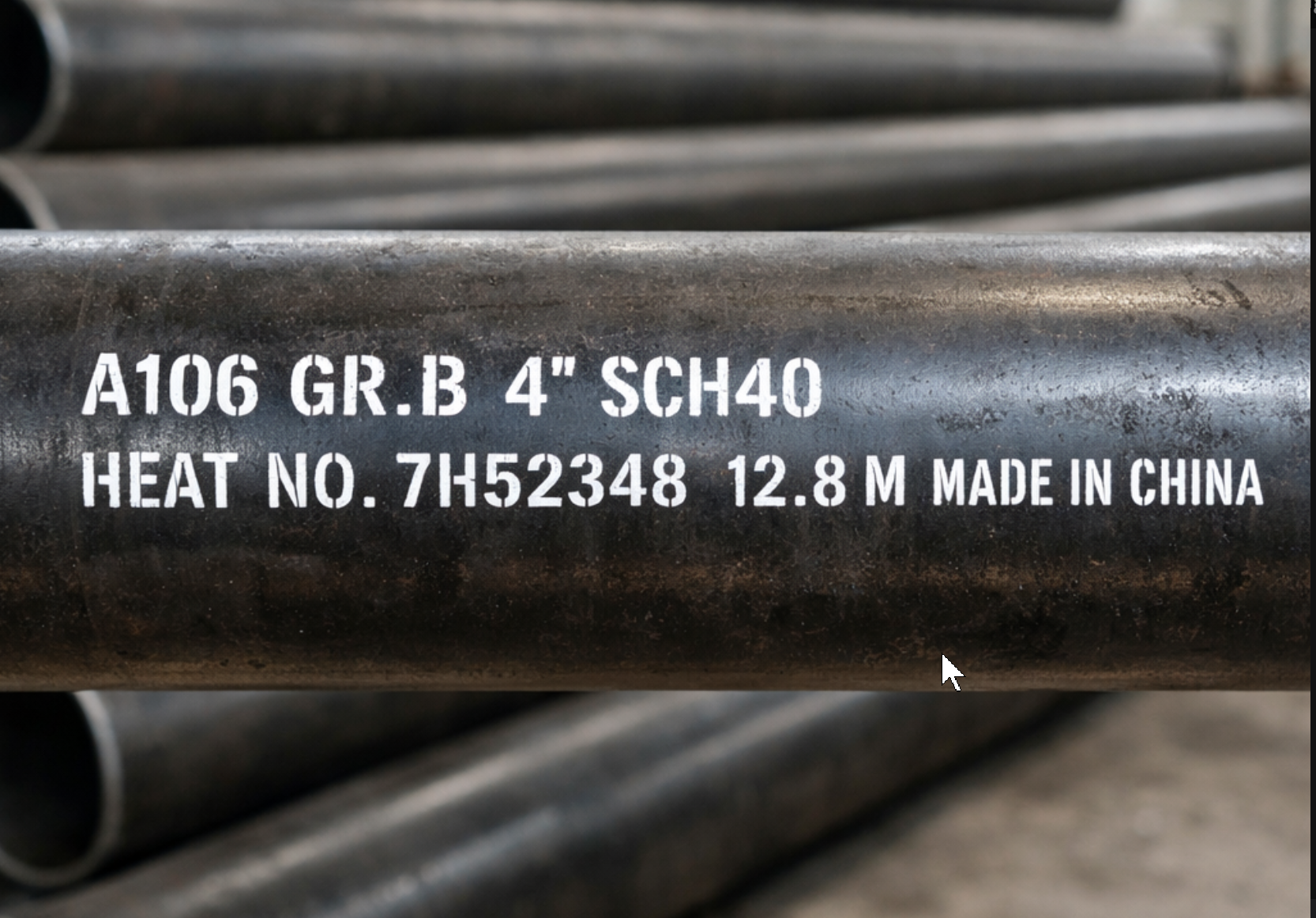

- ASTM A106: This standard covers seamless carbon steel pipe only. It is specifically designed for high-temperature service where structural integrity is paramount.

- ASTM A53: This is a more general-purpose standard. It can be manufactured as Seamless (Type S), Electric Resistance Welded (Type E / ERW), or Furnace Butt-Welded (Type F).

2. Chemical Composition: The Silicon Factor

When comparing the chemical makeup, the presence of

Silicon (Si) is the deal-breaker.

- ASTM A106 Grade B: Contains a minimum of 0.10% Silicon. Silicon acts as a "deoxidizer," making the steel more durable and heat-resistant in high-temperature environments.

- ASTM A53 Grade B: Does not require Silicon. As a result, A53 is less resistant to the "graphitization" that can occur when steel is exposed to high heat over long periods.

3. Temperature and Pressure Suitability

- ASTM A106: The "Gold Standard" for high-temperature service. It is the preferred choice for refineries, power plants, and boilers where temperatures may reach 800°F (427°C).

- ASTM A53: Best suited for low to medium pressure transport of air, water, steam, and oil. It is rarely used in high-heat applications where A106 is required.

4. Mechanical Properties Comparison

While both grades share a similar tensile strength of 60,000 psi (415MPa) and yield strength of 35,000 psi (240 MPa), their testing requirements differ:

Property

| ASTM A106 Grade B

| ASTM A53 Grade B

|

Tensile Strength (min)

| 60,000 psi

| 60,000 psi

|

Yield Strength (min)

| 35,000 psi

| 35,000 psi

|

Silicon Content

| 0.10% min

| Not Required

|

Primary Use

| High-Temp / High-Pressure

| General Purpose / Low-Temp

|

5. Scope and Usage

- ASTM A106 is almost exclusively used in industrial process piping and power plants.

- ASTM A53 is widely used in structural applications, water lines, and HVAC systems.

Can You Substitute A53 for A106?

The short answer is:

It depends on the engineer's approval. While A106 can almost always replace A53 (as it is a "higher" spec), A53 cannot always replace A106 due to the lack of Silicon and the potential for welded seams in Type E pipes.

Conclusion: Which One Do You Need?

Choosing between

ASTM A106 and ASTM A53 depends entirely on your project’s temperature and pressure requirements. For critical high-heat applications, always opt for the

ASTM A106 Grade B Seamless Pipe.

Need a Quote or a Technical Consultation? As a professional

steel pipe manufacturer, Rui Xiang Steel provides full-range support and Mill Test Certificates (MTC) for both A106 and A53 pipes.

Ready to Purchase? Rui Xiang Steel maintains a massive inventory of both

ASTM A106 B Seamless Pipes and ASTM A53 B ERW Pipes. We offer competitive factory prices and fast shipping to [Your Target Regions, e.g., Southeast Asia, Middle East].

[Button: Contact Our Sales Team Today]  Click:521Edit: Ruixiang Steel

Click:521Edit: Ruixiang Steel Time:2025-12-30 12:02:58

Time:2025-12-30 12:02:58